CN

CN info@seacomould.com

info@seacomould.com +86-18969612882

+86-18969612882

What should you pay attention to when designing injection molds

2019-12-06

Opening direction and parting line Each injection molded product must first determine its mold opening direction and parting line at the beginning of the design to ensure that the core slider mechanism is minimized and the parting line's influence on the appearance is eliminated. After the mold opening direction is determined, the product's ribs, buckles, protrusions and other structures are designed to be as consistent as possible with the mold opening direction to avoid pulling the mold core to reduce the seam line and extend the molding time. The life of the mold.

After determining the mold opening direction, you can choose the appropriate parting line to avoid kickback in the mold opening direction, thereby improving the appearance and performance. Proper drafting of the draught angle can prevent the product from being pulled (stretched). The smooth surface of the draft should be ≥0.5 degrees, the surface of fine particles (sand surface) should be greater than 1 degree, and the surface of rough particles should be greater than 1.5 degrees.

Appropriate draft angle can prevent the top of the product from being injured, such as whitening, deformation of the top, and burst. When designing deep cavity structure products, the slope of the outer surface should be greater than the slope of the inner surface as much as possible to ensure that the mold core does not deflect during injection to obtain uniform product wall thickness and ensure material strength.

Product wall thickness Various plastics have a certain wall thickness range, generally 0.54mm. When the wall thickness exceeds 4mm, it will cause too long cooling time and cause shrinkage and other problems. Consider changing the product structure. Uneven wall thickness causes surface shrinkage. Uneven wall thickness can cause pores and weld lines. Reinforcement Proper use of ribs can increase product stiffness and reduce deformation.

After determining the mold opening direction, you can choose the appropriate parting line to avoid kickback in the mold opening direction, thereby improving the appearance and performance. Proper drafting of the draught angle can prevent the product from being pulled (stretched). The smooth surface of the draft should be ≥0.5 degrees, the surface of fine particles (sand surface) should be greater than 1 degree, and the surface of rough particles should be greater than 1.5 degrees.

Appropriate draft angle can prevent the top of the product from being injured, such as whitening, deformation of the top, and burst. When designing deep cavity structure products, the slope of the outer surface should be greater than the slope of the inner surface as much as possible to ensure that the mold core does not deflect during injection to obtain uniform product wall thickness and ensure material strength.

Product wall thickness Various plastics have a certain wall thickness range, generally 0.54mm. When the wall thickness exceeds 4mm, it will cause too long cooling time and cause shrinkage and other problems. Consider changing the product structure. Uneven wall thickness causes surface shrinkage. Uneven wall thickness can cause pores and weld lines. Reinforcement Proper use of ribs can increase product stiffness and reduce deformation.

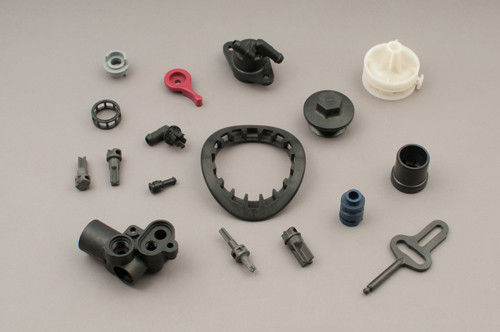

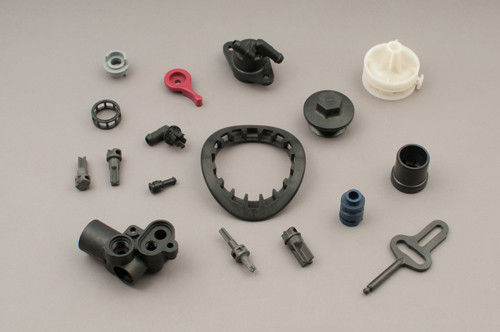

Related Products

Latest Updated

- China automotive mold manufacturing is facing the development trend of 2025

- The major development trend of automotive mould technology

- How to find a good automotive mould supplier and manufacturer in China

- How to make the injection plastic mould gate design

- The most likely defects in the mold injection molding process

- Injection mold repair steps and precautions

- Auto mould making-automould injection moulding company

- How to choose plastic mould supplier in Taizhou China

Relative Articles

- How to make the injection plastic mould gate design

- Corner treatment of mold parting surface for automotive mold design

- Why does the bumper mold adopt the internal fractal structure design

- Key points of plastic mold design

- Design and development of medical equipment and product molds

- Design of Multi-cavity Injection Bottle Cap Mould

- Considerations for the design of plastic bottle cap moulds

- Structural design of beverage bottle cap mold

- Leak-proof design of bottle cap mould

- What are the structural elements to be considered in plastic mold design

Hot Articles

- Mold plating chrome treatment technology is good for mold life

- Analysis of the causes of the fusion line of plastic mold products and corresponding improvement measures

- what are the common problem in the plastic mould injection process

- Leak-proof design of bottle cap mould

- What performance requirements should be met when selecting steel for injection mold

- When Huangyan Mold factory come back to work after coronavirus

- Coronavirus China Wuhan

- How to check the test of the injection mould

- How to choose plastic mould supplier in Taizhou China

- What principles should be followed in the design and development of bumpers mould

- Bottle cap mold manufacturing process

- Six standards for testing the quality of antifreeze bucket mould

Hot tags: china mold maker,taizhou,huangyan, suppliers, manufacturers, factory, maker,customized